FAQ

- Does Goerend still build full transmissions?

- How does a torque converter work?

- What determines stall speed?

- What is true, flash, and breakaway stall speed?

- Lock Up & Speed Ratio

- How do I know if I have a Goerend converter?

- Should I use a threadlocker on my torque converter bolts?

- Torque Converter Rebuild Procedure

- Why is my torque converter overheated?

- Non-VGT Turbo Spool-Up and Boost Behavior

- Why do transmission shafts break?

- Transmission Shaft Overloading

- Transmission Shaft Materials

- What transmission filter should I use?

- What transmission fluid should I use?

- My transmission fluid looks like a strawberry milkshake?

- Do I need Lubeguard additive?

- Normal Transmission Temperatures & Sender Locations

- What's the 48RE transmission pan temperature sender port size?

- Should I use an RTV silicone sealant with my transmission pan?

- Chrysler 47RH, 47RE, and 48RE Transmission Fluid Capacity Instructions

- Dodge 1740 Code

- How do I adjust the low/reverse (rear) band?

- How do I adjust the intermediate (front) band?

- Will a new valve body cure my shifting problems?

- Neutralizing Conditions

- Towing, Sled Pulling & Drag Racing Valve Bodies

- What's a constant-pressure valve body?

- Is there a valve body that works for daily driving, towing, drag racing, and sled pulling?

- Where does the big spring go that comes with a new valve body?

- What does the throttle valve lever do?

- Do all valve bodies need the extra inner front servo piston return spring?

- Should I use the OEM shim with the Goerend Allison 1000 flexplate?

Q: Does Goerend still build full transmissions?

Q: How does a torque converter work?

Let’s start with two wall fans facing each other. If we turn one fan on, the air from this fan will start to turn the other fan, although at a much slower rate than the "drive" fan.

In the case of a torque converter, the drive fan is connected to the engine, and the fan being “driven” is connected to the input shaft of the transmission. In addition, oil is used to transmit the energy between the two fans, as opposed to air in the example scenario.

When a vehicle is stationary, such as at a stop sign, with the transmission in gear and engine at idle, the drive fan that is connected to the engine is spinning so slow that it will not transfer enough oil to turn the driven fan. As the vehicle’s brakes are let off and the throttle is held, the engine speed increases, and the drive fan blows more oil at the driven fan. The driven fan then starts to turn and move the vehicle. This important concept is commonly referred to as fluid coupling.

The drive fan will always turn slightly faster than the driven fan, just like the wall fans. If you were to stick a feather into the blades of the driven wall fan, the driven fan will slow down, but not the drive fan. In a real application, this is just like pulling a heavier trailer. The feather in the driven wall fan is essentially like adding a load to the vehicle.

Q: What determines stall speed?

The two major things that determine the stall speed are engine torque and the torque converter.

This is one way to think about it: You’re on a stationary exercise bike that uses a fan for its pedal resistance. The smaller the fan is, the faster you can pedal. You may be able to pedal up to 200 RPM on the bike with a small fan, but only be able to pedal up to 50 RPM if you fit a bigger fan on the bike. The small fan was able to stall you at 200 RPM and the bigger fan stalled you at 50 RPM. Two different fans, two different stall speeds.

Now a professional athlete hops on the bike. With the big fan, they may be able to pedal 100 RPM, as opposed to your 50 RPM.

To compare this to the engine torque and torque converter, you must remember that a torque converter is nothing more than two fans. One fan is connected to the engine and the other fan is connected to the transmission. The fan connected to the engine blows oil at the fan connected to the transmission. Once the engine fan blows enough oil at the transmission fan, the transmission fan will start to rotate. The vehicle will then start to move.

Just like the exercise bike analogy, if you install a torque converter with bigger fan blades into a vehicle with the same engine torque, the stall speed will be lower. If you add more horsepower to the engine, just like the athlete hopping on the exercise bike, the stall speed will increase.

Now let’s talk about air. It's all about the oxygen. You’ll be able to pedal harder on the bike at sea level than on the top of a mountain because you’ll be able to breathe better, since there is more oxygen in the air. Similar to your lungs, an engine is nothing more than an air pump that uses fuel. The fuel an engine uses must react with oxygen in order to push the piston down and turn the crankshaft.

The higher the elevation, the less oxygen the engine has to work with, and the less fuel that can be injected to react with the oxygen. By using less fuel, it means the power input into the converter will be lower, resulting in a lower stall speed. Normally, the higher the elevation, the higher the stall speed that is needed in order to help offset the lack of oxygen that is present at sea level.

The engine turbo also can make a huge difference. Like the converter, the turbo is also a set of fans. The drive fan is located in the exhaust of the engine and it’s the exhaust flow makes this fan spin.

The driven fan of the turbo is connected to the drive fan and sits on the intake side of the engine. The driven forces oxygen into the engine so it can burn more fuel, resulting in more power.

A turbo with bigger fans takes longer to spool up and start to blow more air into the engine. Because of this, it takes longer to get oxygen into the engine cylinders to burn fuel. This is called turbo lag.

Q: What is true, flash, and breakaway stall speed?

To explain stall speed, let’s start with a true full stall speed.

True stall speed is tested by putting the vehicle in drive and holding the throttle wide open while simultaneously holding the brake, so the vehicle remains stationary. When this happens, the torque converter will stall the engine at a certain RPM. When stalled, the engine will not be able to increase RPM until the vehicle is allowed to move. This is a true full stall. Do not test for true stall, as it can damage transmission shafts and overheat the torque converter. We have specialized equipment we use to perform this test.

The next stall speed is generally known as breakaway stall speed. A vehicle in drive is stopped on an incline and the throttle was held enough to hold the vehicle in place, but not enough to move the vehicle uphill. Once the throttle is held enough to start creeping the vehicle uphill, breakaway stall speed has been reached. For example, if the engine RPM required to hold the truck is 1100 RPM, and an increase of 25 RPM started to move the truck, the breakaway stall speed would be 1125 RPM.

The last stall speed is generally known as flash stall speed. The flash stall speed takes effect under hard acceleration. A vehicle idling in drive and the throttle is then held wide open. The engine starts to accelerate quickly, then temporarily pause at an RPM as it starts to pull the vehicle. If the engine took 1.5 seconds to get from an idle to 1500 RPM when floored, then took another two seconds to get from 1500 RPM to 2000 RPM, this would mean the flash stall speed would be 1500 RPM.

When we lower the stall of a converter, it can also lower the breakaway stall speed as well as the flash stall speed. Lowering the stall makes the engine work at a lower RPM for any given road speed and in most cases, will increase fuel mileage.

Q: Lock Up & Speed Ratio

Once a vehicle gets up to speed there is a mechanism called a lock up clutch that locks the driven fan of the torque converter to its front cover, which is bolted to the engine. When this occurs, the drive fan and driven fan turn at the same RPM, with no loss of power in fluid coupling.

When the drive and driven fan are not locked together, heat is generated inside the converter. The greater the RPM difference between the drive and driven fan, the higher the temperature will reach. This heat is essentially lost power which results in a lower transmission life, performance, and fuel economy.

The loss of energy in this process can be calculated. A converter’s drive fan (impeller) may be turning at 2500 RPM and the driven fan (turbine) may be turning at 1800 RPM. By dividing the turbine RPM by the impeller RPM, we can find the efficiency of the converter, which is 72% at the given speeds of the impeller and turbine. This efficiency rate is also known as a converter’s speed ratio. When the vehicle gets up to speed and the lock up clutch engages, the engine and impeller RPM match the RPM of the turbine.

Low stall converters will be able to achieve a higher speed ratio before lock up. When low stall converters lock up, their RPM drop is substantially less, therefore easier on the converter’s clutch lining and will reduce clutch glazing. Because the fluid coupling of a low stall converter is more efficient, they are able to transfer more power, create less heat, and deliver better fuel economy than high stall converters.

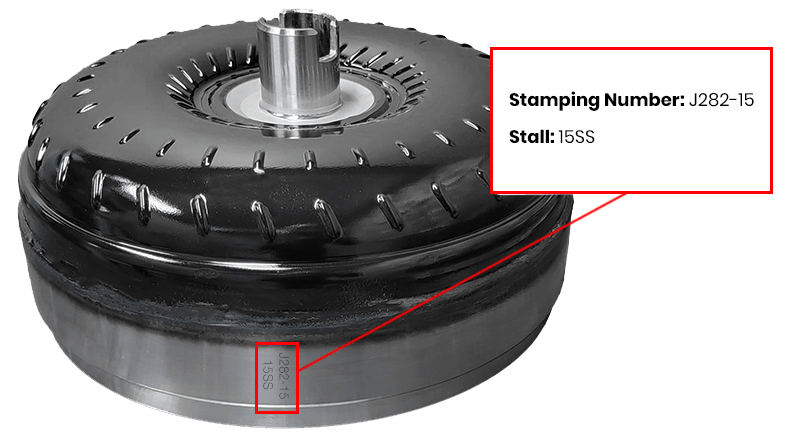

Q: How do I know if I have a Goerend converter?

If your converter originated from Goerend, there will be a series of numbers stamped into the outside cover. To find this series of numbers follow these steps:

- Remove inspection plate

- Rotate converter until you see the stamping number

Q: Should I use a threadlocker on my torque converter bolts?

While you don't need to use a threadlocker, such as Loctite, on your torque converter bolts, we would recommend using Loctite Blue if you choose to use a threadlocker.

Q: Torque Converter Rebuild Procedure

- All parts and internal components are cleaned and inspected

- Impeller, turbine, stator, clutch plates, damper assemblies, and covers are all balanced individually

- Torque converter is assembled and multiple internal and external dimensional inspections are completed

- Torque converter is welded together by TCRS alignment equipment with sub-0.003 runout tolerances

- Torque converter is leak-tested under water, while under pressure

- Torque converter is balanced as a unit and the runout tolerance is inspected again

- Total height of the torque converter is inspected

- Internal end-play is inspected

- Lock up clutch is applied and inspected for leaks and holding power

- Lock up clutch is released; the lock up clutch and turbine are spun while the impeller is stationary

- Lock up clutch is examined to insure proper release and no interference between internal components

- Impeller hub is lubricated and a protector cap is placed

- New bolts are provided where necessary

Q: Why is my torque converter overheated?

Q: Non-VGT Turbo Spool-Up and Boost Behavior

Q: Why do transmission shafts break?

Q: Transmission Shaft Overloading

Q: Transmission Shaft Materials

Q: What transmission filter should I use?

For best results, use Mopar transmission filters.

We prefer to use the early style open element filter because it will seal up better. The exception to this would be the deep factory stamped pan. This pan should take the late style plastic filter because it will sit deeper in the fluid within the pan.

Q: What transmission fluid should I use?

Chrysler 47RH, 47RE, and 48RE transmissions have used Dexron fluid, Chrysler 7176 fluid, Mopar type 3 fluid, and now Mopar type 4 fluid. We have used all of these fluids without any problems. There are many fluids you can use, and most synthetics are fine to use as well.

Q: My transmission fluid looks like a strawberry milkshake?

Q: Do I need Lubeguard additive?

Lubeguard will help keep the transmission cooler, and is supposed to help clutches last longer. It's not a necessity, but those would be the potential benefits if you choose to use it. You can purchase Lubeguard additive at a NAPA store. Part #: BK 7652966. This is transmission fluid additive, not additive for the gas tank.

Q: Normal Transmission Temperatures & Sender Locations

Q: What's the 48RE transmission pan temperature sender port size?

Q: Should I use an RTV silicone sealant with my transmission pan?

Q: Chrysler 47RH, 47RE, and 48RE Transmission Fluid Capacity Instructions

OE Pan: Holds approximately 14 qts.

- Pour in 6 quarts of transmission fluid into dipstick tube.

- Start vehicle.

- Add 7 - 8 more quarts of transmission fluid into dipstick tube.

- Check fluid level. The transmission must be in neutral because the factory valve body on these transmissions will not fill the converter in park.

- Look at both sides of the dipstick and take the reading from the low side.

- Add transmission fluid until full.

- Recheck fluid level after driving 5 - 10 miles.

Goerend Pan: Holds approximately 16 qts.

- Pour in 8 quarts of transmission fluid into dipstick tube.

- Start vehicle.

- Add 6 - 8 more quarts of transmission fluid into dipstick tube.

- Check fluid level.

- The transmission must be in neutral because the factory valve body on these transmissions will not fill the converter in park.

- Look at both sides of the dipstick and take the reading from the low side.

- Add transmission fluid until full.

- Recheck fluid level after driving 5 - 10 miles.

Double Deep Pan: Holds approximately 19 qts.

- Pour in 8 quarts of transmission fluid into dipstick tube.

- Start vehicle.

- Add 9 - 11 more quarts of transmission fluid into dipstick tube.

- Check fluid level. The transmission must be in neutral because the factory valve body on these transmissions will not fill the converter in park.

- Look at both sides of the dipstick and take the reading from the low side.

- Add transmission fluid until full.

- Recheck fluid level after driving 5 - 10 miles.

Q: Dodge 1740 Code

On a late model truck, usually 2004 - 2007, any stall speed different than the factory stall (17SS or DA) can set a 1740 code. This code will turn on the check engine light but will not affect the operation of the transmission or engine. This code sets because the computer constantly monitors the engine RPM and compares it to the throttle angle and road speed.

With a lower stall converter, the computer sees the lower engine RPM and thinks the lock up or overdrive solenoid is mechanically stuck on. The computer can check for electrical faults and will not detect any, and thinks the lower RPM is due to the converter being locked up or the transmission is in overdrive, even though it's not. Most programmers can erase the 1740 code. This code will not affect the transmission or engine operation if both are working normally otherwise.

Q: How do I adjust the low/reverse (rear) band?

Tighten the adjuster to 72 inch-pounds and loosen 3¼ full turns.

Q: How do I adjust the intermediate (front) band?

If a vehicle is equipped with a Goerend valve body, loosen the lock nut and tighten the adjustment bolt to 72 inch-pounds and finally loosen 2¼ turns.

Q: Will a new valve body cure my shifting problems?

Many shifting problems can be cured by a valve body, but the shift timing is controlled by the computer. On a Chrysler 47RH and older transmissions, the 3-4 and converter lock up is computer controlled. On a Chrysler 47RE and newer transmissions, all shifts will be controlled by the computer. This means that a bad input to the computer, such as a bad throttle position sensor or output shaft speed sensor, can affect the shifting. This would then seem like a valve body problem, even though it is not.

Q: Neutralizing Conditions

Some vehicles have problems while accelerating at about 3/4 throttle around 40 MPH, when trying to shift from 2nd to 3rd gear. The transmission will neutralize and the engine revs up, just like it shifted to neutral instead of 3rd gear. If the throttle is then let off, it bangs into 3rd gear.

A Goerend valve body will correct this, as long as the governor solenoid is in good condition.

Many valve body builders do not know that the torque converter circuit is regulated to 130 PSI from factory, so it is common practice to eliminate this circuit and give the converter full line pressure. This practice is the main cause of ballooned converters. A Goerend valve body will have the proper regulation in the converter circuit.

Q: Towing, Sled Pulling & Drag Racing Valve Bodies

We want a smooth shift on a towing valve body. This helps keep shafts and planetary gears from breaking due to the shock of brutal shifts. We also build the valve body so you can downshift from 4th to 3rd and from 3rd to 2nd with the converter locked in case you have an exhaust brake. If a toggle switch is installed, you can also lock the converter while in manual 2nd so the converter will not overheat while towing a heavy load up a steep grade.

With a sled pulling valve body, You'll be capable of locking the converter clutch in 1st, 2nd, 3rd, and overdrive and also be able to back shift from overdrive to 3rd, 2nd, and 1st with the converter locked.

On a drag racing valve body, we normally lock the converter right after the 1-2 shift. We're able to build the valve body so it will not lock the converter in 1st. In doing so, you'll be able to turn the lock up switch on while at the starting line without killing the engine, and as soon as it shifts to 2nd, the converter will automatically lock up.

Q: What's a constant-pressure valve body?

Normally, the pressure that applies the clutches and bands in a transmission will be low at idle and high at full throttle. With a constant-pressure valve body, the pressure is high at all times, both at idle and wide open throttle. Constant-pressure valve bodies are only recommended for high-horsepower and racing applications. Constant-pressure valve bodies shift aggressively and can cause fatigue to internal transmission components over time.

Q: Is there a valve body that works for daily driving, towing, drag racing, and sled pulling?

Yes and no. Up to about 500 horsepower, the same valve body can work well for all. Once above 500 horsepower, there are things needed to be modified on the valve body that would be specific to drag racing and sled pulling that would not be made to a daily driver or tow rig valve body.

Q: Where does the big spring go that comes with a new valve body?

This spring goes into the intermediate (front) band apply servo along with the original spring. This is the servo that applies the front band.

Q: What does the throttle valve lever do?

The TV lever basically does three things:

1: It makes the transmission line pressure increase when you increase the throttle. When you step into the throttle for more power the line pressure goes up so the clutches and bands don't slip.

2: It will delay the shifts with increased throttle. You wouldn’t want the transmission to be in high gear at 40 MPH at wide open throttle, but you would want the transmission to be in high gear at light throttle.

3: At light throttle, the TV lever, along with governor pressure and the 1-2 shift control valve, dictate how fast the front band is released. The band is released quickly at light throttle so there is no bind up. The front band is released slower at wide open throttle so there is no cut loose or engine flare.

With a ranging-pressure manual valve body, you would have the TV lever adjusted just like a normal valve body for smooth shifts at light throttle, and quicker shifts at full throttle.

With a constant-pressure manual valve body, the only thing the TV lever will do is release the front band sooner at light throttle, or slower at heavy throttle. We would use an old choke cable, such as an old carburetor, and connect it to the TV lever. At light throttle, the lever would be all the way forward for a smoother 2-3 shift. At full throttle, you would pull the choke cable so the lever is all the way back so there was not a flare during the shift.

Q: Do all valve bodies need the extra inner front servo piston return spring?

This is a calibration spring for the 2-3 shift. We use this spring as the calibration spring because the other calibration points are inside the transmission, meaning we would have to remove the entire transmission to calibrate the shift.

Normally, we would start with this spring installed. If there was a cutloose or engine flare during the 2-3 shift, we could remove this spring to eliminate the cutloose. The opposite of the cutloose is a bind up shift. This can break an input shaft, even if it is billet steel. It's better to start with this spring installed and remove it later, than to start without the spring and encounter a bind up shift which could damage the input shaft.

To install or remove this spring, the transmission does not need to be removed.