Goerend Transmission - Converters

Torque converters have been our focus since 1978. We design our converter components and also manufacture them from start to finish using 14 in-house CNC machines. This ensures accurate dimensions that work with your transmission. This also means you are communicating directly to the manufacturer, which is very rare in this industry. We have testing capabilities unmatched by anyone else, including both a chassis dynamometer and custom built transmission dynamometer. We use our advanced testing power to analyze critical data such as converter K-factor and torque ratio. This advanced ability to test our converters combined with decades of transmission knowledge is what makes us the highest standard in performance diesel torque converters.

Browse Converters Products

Items 1-34 of 34

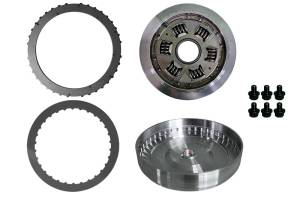

Chrysler 47RE | 48RE

Description:

The items in this kit must be used together in the same vehicle.

Item #: DTC-SXD-(#)

Condition:

New

Current build time of 5-7 days.

Price: $3,599.00

Ford 6R140

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: FTCK1-6R140

Condition:

New

Price: $2,200.00

Current build time of 6-8 days.

Price: $2,200.00

Ford 6R140

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: FTCK2-6R140

Condition:

New

Price: $2,200.00

Allison 10L1000

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: ATCK-10L1000

Condition:

New

Price: $1,845.00

Current build time of 5-7 business days.

Price: $1,845.00

Not Available

Current build time of 6-8 business days.

Price: $1,650.00

Current build time of 6-8 days.

Price: $1,650.00

Aisin AS68RC

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: DTCK-AS68RC

Condition:

New

Not Available

Price: $1,650.00

Current build time of 3-5 days.

Price: $1,545.00

Current build time of 6-8 days.

Price: $1,545.00

Allison 1000 6SPD (2006 - 2016)

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: ATCK-L3D

Condition:

New

Price: $1,545.00

Current build time of 1-3 days.

Price: $1,395.00

Chrysler 68RFE

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: DTCK-68RFE

Condition:

New

Price: $1,395.00

Ford E4OD | 4R100

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: FTCK-4R100

Condition:

New

Price: $1,395.00

Current build time of 4-6 days.

Price: $1,395.00

Current build time of 5-7 days.

Price: $1,395.00

Ford 5R110W

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: FTCK-5R110W

Condition:

New

Price: $1,395.00

Ford 6R140

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: FTCK3-6R140

Condition:

New

Price: $1,350.00

Please Call for Availability

Current build time of 1-3 days.

Chrysler 47RE | 48RE

Description:

Current assembly time of 3-5 days. Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: DTCK-48RE

Condition:

New

Price: $1,195.00

Current build time of 2-4 days.

Price: $1,195.00

Current build time of 4-6 days.

Price: $800.00

Please Call for Availability

GM 6L80 | 6L90

Description:

Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: D-6L90_COVER

Condition:

New

Price: $299.00

Ford 6R140

Description:

Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: FTCK-PISTON

Condition:

New

Price: $249.00

GM 6L80 | 6L90

Description:

Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: D-6L90_PISTON

Condition:

New

Price: $149.00

GM 6L80 | 6L90

Description:

Wholesale purchase only: Please visit our Parts Distributor Map to locate a distributor.

Item #: GM_6L80E_Spring_Cage

Condition:

New

Price: $49.00

Ford 4R100 | 5R110W | 6R140

Description:

This bolt is designed for use with a Goerend torque converter. This bolt will not fit OEM torque converter applications.

Item #: FTC-BOLTS-(ARP)

Condition:

New

Price: $5.00

Items 1-34 of 34