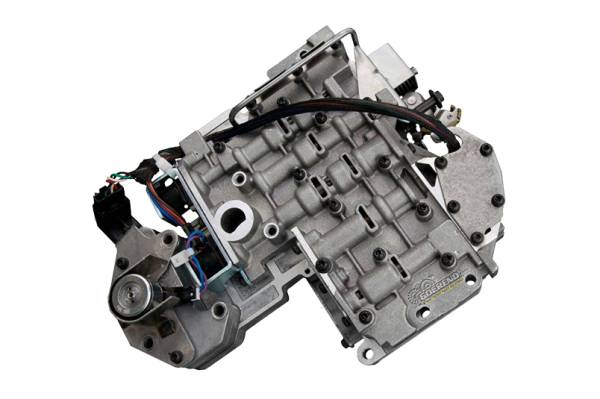

Valve Body, High-Pressure

Chrysler 47RE | 48RE

Description

We like to keep shifts smooth as possible. Not a slippery long drawn out shift, but a quick and smooth shift. When you step into the throttle, the engine power increases. The pressure in the transmission needs to increase too. Our valve bodies have a much faster and steeper pressure rise than other valve bodies.

Factory valve bodies normally have an idle pressure of 60 PSI and a full throttle pressure near 100 PSI. Goerend valve bodies have an idle pressure of 70 - 90 PSI, and a pressure rise to 150 - 190 PSI at full throttle. Driving habits and vehicle use will dictate what pressures are needed.

Goerend Difference:

- Dynomometer-tested on an Answermatic 4000 Valve Body Test System using Superflow WinDyn software

- Built in-house

- Specifically calibrated for Goerend torque converters

- Constant pressure setup available

- Manual setup available

Dump Valve

We utilize a technique that has been in the gas racing world for years, the torque converter dump valve, which drains oil from the torque converter while spooling at the line, allowing the engine to gain RPM and rise to the desired level before launching. When coupled with a Non-Lock Up Torque Converter and Constant High Pressure Manual Trans-Brake Valve Body, drivers have seen faster and more consistent runs. The dump valve setup requires no major changes to the transmission, only additional wiring to control the solenoids. Other advantages to this system are less rotational weight and overall maintenance, with higher pressure to hold the transmission clutches and no torque converter clutches.

Apply Regulation

Some valve bodies are limited on how much line pressure that can be run due to the stretching and deformation of the torque converter's impeller due to over-pressurization, known as ballooning. Our apply-regulated valve body regulates torque converter lock-up apply pressure separately from main line pressure. This allows higher pressures in the transmission for holding smaller diameter transmission clutches, while a lower, safe pressure is used to hold the large diameter converter clutches without damaging the torque converter, pump, or shaft.

Articles:

Videos

FAQ

Many shifting problems can be cured by a valve body, but the shift timing is controlled by the computer. On a Chrysler 47RH and older transmissions, the 3-4 and converter lock up is computer controlled. On a Chrysler 47RE and newer transmissions, all shifts will be controlled by the computer. This means that a bad input to the computer, such as a bad throttle position sensor or output shaft speed sensor, can affect the shifting. This would then seem like a valve body problem, even though it is not.

Neutralizing Conditions

Some vehicles have problems while accelerating at about 3/4 throttle around 40 MPH, when trying to shift from 2nd to 3rd gear. The transmission will neutralize and the engine revs up, just like it shifted to neutral instead of 3rd gear. If the throttle is then let off, it bangs into 3rd gear.

A Goerend valve body will correct this, as long as the governor solenoid is in good condition.

Many valve body builders do not know that the torque converter circuit is regulated to 130 PSI from factory, so it is common practice to eliminate this circuit and give the converter full line pressure. This practice is the main cause of ballooned converters. A Goerend valve body will have the proper regulation in the converter circuit.

Towing, Sled Pulling & Drag Racing Valve Bodies

We want a smooth shift on a towing valve body. This helps keep shafts and planetary gears from breaking due to the shock of brutal shifts. We also build the valve body so you can downshift from 4th to 3rd and from 3rd to 2nd with the converter locked in case you have an exhaust brake. If a toggle switch is installed, you can also lock the converter while in manual 2nd so the converter will not overheat while towing a heavy load up a steep grade.

With a sled pulling valve body, You'll be capable of locking the converter clutch in 1st, 2nd, 3rd, and overdrive and also be able to back shift from overdrive to 3rd, 2nd, and 1st with the converter locked.

On a drag racing valve body, we normally lock the converter right after the 1-2 shift. We're able to build the valve body so it will not lock the converter in 1st. In doing so, you'll be able to turn the lock up switch on while at the starting line without killing the engine, and as soon as it shifts to 2nd, the converter will automatically lock up.

What's a constant-pressure valve body?

Normally, the pressure that applies the clutches and bands in a transmission will be low at idle and high at full throttle. With a constant-pressure valve body, the pressure is high at all times, both at idle and wide open throttle. Constant-pressure valve bodies are only recommended for high-horsepower and racing applications. Constant-pressure valve bodies shift aggressively and can cause fatigue to internal transmission components over time.

Is there a valve body that works for daily driving, towing, drag racing, and sled pulling?

Yes and no. Up to about 500 horsepower, the same valve body can work well for all. Once above 500 horsepower, there are things needed to be modified on the valve body that would be specific to drag racing and sled pulling that would not be made to a daily driver or tow rig valve body.

Where does the big spring go that comes with a new valve body?

This spring goes into the intermediate (front) band apply servo along with the original spring. This is the servo that applies the front band.

Do all valve bodies need the extra inner front servo piston return spring?

This is a calibration spring for the 2-3 shift. We use this spring as the calibration spring because the other calibration points are inside the transmission, meaning we would have to remove the entire transmission to calibrate the shift.

Normally, we would start with this spring installed. If there was a cutloose or engine flare during the 2-3 shift, we could remove this spring to eliminate the cutloose. The opposite of the cutloose is a bind up shift. This can break an input shaft, even if it is billet steel. It's better to start with this spring installed and remove it later, than to start without the spring and encounter a bind up shift which could damage the input shaft.

To install or remove this spring, the transmission does not need to be removed.

What does the throttle valve lever do?

The TV lever basically does three things:

1: It makes the transmission line pressure increase when you increase the throttle. When you step into the throttle for more power the line pressure goes up so the clutches and bands don't slip.

2: It will delay the shifts with increased throttle. You wouldn’t want the transmission to be in high gear at 40 MPH at wide open throttle, but you would want the transmission to be in high gear at light throttle.

3: At light throttle, the TV lever, along with governor pressure and the 1-2 shift control valve, dictate how fast the front band is released. The band is released quickly at light throttle so there is no bind up. The front band is released slower at wide open throttle so there is no cut loose or engine flare.

With a ranging-pressure manual valve body, you would have the TV lever adjusted just like a normal valve body for smooth shifts at light throttle, and quicker shifts at full throttle.

With a constant-pressure manual valve body, the only thing the TV lever will do is release the front band sooner at light throttle, or slower at heavy throttle. We would use an old choke cable, such as an old carburetor, and connect it to the TV lever. At light throttle, the lever would be all the way forward for a smoother 2-3 shift. At full throttle, you would pull the choke cable so the lever is all the way back so there was not a flare during the shift.

Shipping Information

- Item Requires Shipping

- 35.0 lbs.

- W14.0000” x H9.0000” x L14.0000”

- This item ships in its own box.